Features

- Spindle utilizes class 7210 (P4, ABEC-7) precision angular bearings for the industry-leading spindle taper runout of 0.00012″

- The chromium-Molybdenum spindle is fully hardened through a carbonizing treatment and is precisely ground to maintain strict tolerances

- Seamless, one-piece, steel quill is induction hardened and chromed for increased strength and precision ground for greater accuracy

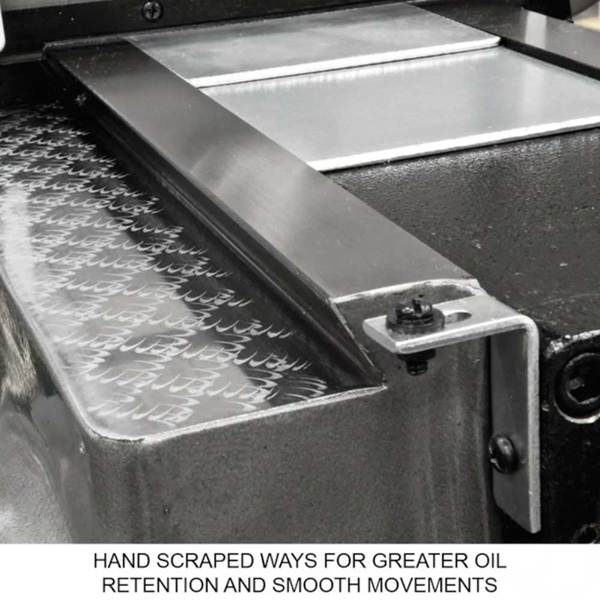

- The Y and Z-Axis ways are hands scraped to a minimum of 16 points per square inch for greater oil retention and smooth movements

- Heat treated and polished lead screws are supported by thrust bearings ensuring smooth, incremental movements of the table under load

- The table and saddle backlash is controlled by an advanced double nut design that eliminates end-play for precisely controlled lateral movements

- A patented vari-disc key provides upt to ten times the wear resistance than aluminum or brass keys

- Variable speed pulleys are ground and multiplane dynamically balanced, reducing vibration and ensuring smooth speed transitions

- Ball-bearing support of the motor shaft ensures proper loading, support, and alignment for quiet, accurate operation at any speed

- The hardened and ground table provides a stable and accurate platform for milling a diverse variety of materials

- Every thirty minutes, with a flow of 3 to 6 cc/cy your Elite mill is automatically lubricated

- Stainless steel Y-Axis way cover provides extra years of protection over the standard sheet metal cover

- Certified Meehanite castings retain their tolerances and remain rigid through many years of machining

- The electronic spindle brake, when activated, interrupts power to the spindle to prevent accidental start-ups

- The mounted control box houses major mill functions as well as an emergency stop button

- For added safety, the ETM-949EVS Mill follows strict guidelines and electrical requirements to be certified by CSA Group

- Standard Equipment

- Spindle Safety Guard

- Halogen Machine Lamp

- Dual Locks On All Surfaces

What’s in The Box

- EVS-949 Mill w/ 3-Axis Newall DP700 (Knee) DRO and Servo X, Y, Z-Axis Powerfeeds and Air Powered Draw Bar – 894434

- Owner’s Manual

Warranty

- 3 Year Limited Factory Warranty

- 30 Day Satisfaction Guaranteed

Specifications

| SKU | 894434 |

| Brand | Jet |

| Volts | 230V |

| Horsepower | 3 |

| Phase | 3 |

| Number of Axis | 3 (Knee) |

| Style | Variable Speed |

| Digital Readout | Newall DP700 |

| Powerfeed | X, Y and Z-Axis |

| Power Draw Bar | USA Made |

| Table Size (L x W) | 9 x 49 in |

| Spindle Taper (In. x TPI) | R-8 |

| Quill Diameter | 3-3/8 in |

| Number of Spindle Speeds | Electronic Variable |

| Range of Spindle Speeds (RPM) | 60 – 5,000 |

| Quill Down Feed Rates (IPR) | 0.0015 – 0.003 – 0.006 |

| Spindle Travel | 5 in |

| Head Movement | 90 R and L 45 F and B degrees |

| Max Distance Spindle to Table | 18-3/4 in |

| Distance Spindle to Column (Max.) | 21-2/5 in |

| Distance Spindle to Column (Min.) | 6-1/2 |

| Collet Capacity | 1/8 – 7/8 in |

| Table Longitudinal Travel | 36 in |

| Table Cross Travel | 12 in |

| T-Slots Number and Size | 3 and 5/8 in |

| T-Slot Centers | 2-1/2 in |

| Work Table Weight Capacity | 550 lbs |

| Travel of Knee | 16 |

| Travel of Ram | 14 |

| Amperage Draw at 230V 3Ph | 18 |

| Dimensions (L x W x H) | 68 x 63 x 84 in |

| Weight | 2300 lbs |

GIVE US A CALL: 1-800-629-3325

Expert Service

Factory Warranties

Fast Shipping

Payment Options

Be the first to review “JET 894434 EVS-949 Mill 3 Axis Newall DP700 Servo X,Y,Z-Axis w/ USA Air Draw Bar” Cancel reply

Related products

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Sale!

Reviews

There are no reviews yet.